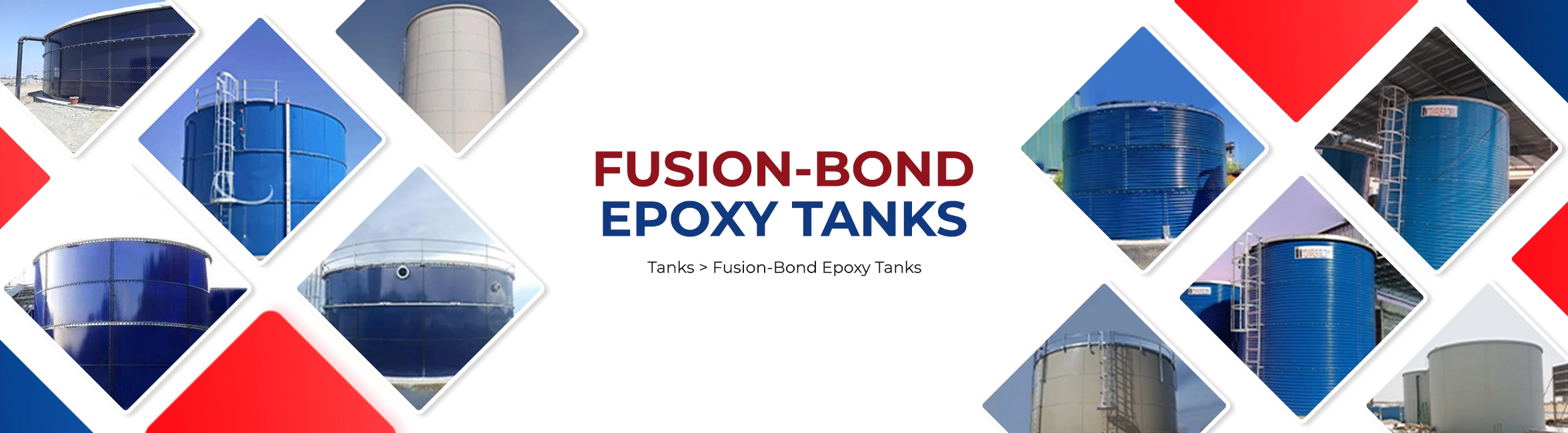

WHAT ARE FBE COATED TANKS?

Fusion Bond Epoxy is an electrostatically applied coating system with superior coverage and uniform coating thickness. Thermoset resin fusion bonded epoxy used on the internal surface combined with the ultra durable polyester on external surface ensures high performance corrosion resistance for water and waste water storage tanks.

Fusion Bond Epoxy (FBE) Coated Prefabricated Tanks are made by fusing epoxy to Zincalume plates. This process enhances the properties of Zincalume, making it more resistant to environmental conditions. The fusion coating increases resistance to weathering and corrosion and allows the tanks to store a wide range of liquids such as clear water, wastewater, organic waste, and oil.

.webp)

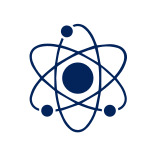

PROCESS AND TECHNOLOGY

Fusion Process

Tank panels undergo an epoxy coating both inside and outside. This is done in a specialized furnace at temperatures between 120-240°C, ensuring maximum durability and long-lasting protection.

Surface Protection

Connecting materials and shell accessories undergo various advanced treatments to enhance surface durability, ensuring they are well-protected from wear, corrosion, and harsh environmental factors.

APPLICATION OF FBE TANKS

Liquid Storage

Reliable and versatile solutions for safely storing a wide range of liquids.

Environmental Facilities

Essential for facilities like wastewater treatment and biogas stations..

BENEFITS OF EPOXY COATING FOR BOLTED TANKS

- Certified Coating: Potable water certified (WRAS/NSF).

- Environmental Compliance: Complies with European REACH Regulations, ensuring global safety and environmental standards.

- Corrosion Protection: Provides excellent corrosion resistance and long-term performance without requiring cathodic protection.

- Maintenance: Panels can be recoated after their service life to extend product lifecycle.

- Mechanical Strength: Offers better impact and flexibility resistance, reducing damage during transportation and handling.

- Repairability: Easily repairable on-site if damaged.

- UV Resistance: External polyester surface undergoes Florida outdoor exposure testing for UV resistance and durability in intense sunlight conditions.